Introduction to Vevor Powder Coating Machines

Vevor Powder Coating Machines are renowned for their affordability, durability, and versatility, catering to both DIY enthusiasts and small-scale industrial users. These machines apply electrostatic powder coatings to metal surfaces, creating a robust, eco-friendly finish without solvents. Key features include adjustable voltage controls, compact designs, and efficient powder recovery systems. Ideal for automotive parts, furniture, and tools, Vevor machines balance performance and budget, making them a top choice for hobbyists and startups. With intuitive operation and low maintenance, Vevor powder coating equipment ensures professional results at a fraction of industrial-grade costs.

1. Vevor Powder Coating Machine Components and Structure

A Vevor Powder Coating Machine comprises an electrostatic spray gun with adjustable settings (30–100 kV), a powder feed system (hopper and fluidized bed), and a portable curing oven (up to 200°C). The compact design integrates a grounding cable for safety and a recovery module to recycle excess powder, minimizing waste. Advanced models feature digital temperature controls and ergonomic gun handles for precision. Built with stainless steel and heat-resistant materials, Vevor machines prioritize durability and ease of cleaning, ideal for workshops with limited space.

2. Applications of Vevor Powder Coating Machines

Vevor Powder Coating Machines excel in coating automotive components (wheels, brackets), home furniture (metal chairs, racks), and DIY projects (bicycle frames, tools). Small businesses use them for artisanal metal crafts or restoration work, while agricultural workshops apply coatings to machinery parts for rust prevention. Their portability and low energy consumption also make them suitable for garage setups and prototype development in the renewable energy sector, such as coating solar panel mounts.

3. Vevor Powder Coating Machine Design Considerations

Vevor Powder Coating Machine’s design emphasizes safety with insulated cables, overload protection, and automatic shutoff for overheating. The compact curing oven reduces heat loss, while modular components allow easy upgrades, like adding a larger hopper. Users must ensure proper ventilation to avoid powder inhalation and maintain a clean workspace to prevent contamination. For Vevor Powder Coating Machine maintenance, regularly clean the gun nozzle and replace filters to ensure consistent spray patterns and powder recovery efficiency.

4. How to Choose the Right Vevor Powder Coating Machine

Select a Vevor machine based on project size, material type, and budget. For occasional DIY use, the Vevor 10L Manual Model (500–700) suffices. High-volume users should opt for the Vevor 30L Semi-Auto System (1,200–1,500) with a conveyor belt adapter. Check voltage compatibility (110V/220V) and curing oven capacity. Prioritize models with powder coating gun warranties and included accessories (gloves, masks). Compare Vevor powder coating machine prices across retailers for seasonal discounts.

5. Vevor Powder Coating Machine Q&A

Q: How to troubleshoot uneven coating on a Vevor machine?

A: Adjust the gun’s voltage, ensure proper grounding, and check the Vevor powder fluidization in the hopper.

Q: Are Vevor machines suitable for outdoor use?

A: Yes, but store components in dry conditions to prevent moisture from clumping powder.

Q: What safety gear is needed for Vevor machines?

A: Wear an N95 mask, anti-static gloves, and goggles to comply with Vevor coating equipment safety standards.

Q: Can Vevor coat non-metallic materials?

A: No, these machines are optimized for conductive metals like steel and aluminum.

Q: How long does a Vevor curing oven take to heat up?

A: Typically 10–15 minutes to reach 180°C, depending on ambient temperature.

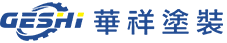

Disclaimer: Enhance your coating process with advanced electrostatic powder coating machines, precision powder coating spray guns, comprehensive powder coating systems, and efficient powder coating lines from Hangzhou Huaxiang Coating Equipment Co., Ltd. Designed for reliability and high-quality finishes, our solutions meet all your industrial powder coating machine needs. Contact us at sale3@cncolourspray.com